Ceramic Products

Find the Reliable Ceramic Solutions for Industrial Applications

Unick Control System, located in India, is a leading manufacturer and supplier of ceramic lined pipe fittings supplier innovative solutions for industries facing wear, corrosion, and high temperatures. At Unick Control System, we manufacture a range of durable ceramic products to ensure reliability and prolonged asset life under demanding conditions.

High Performance Ceramic Products

At Unick Control System, we manufacture and supply an extensive and comprehensive range of ceramic solutions that include:

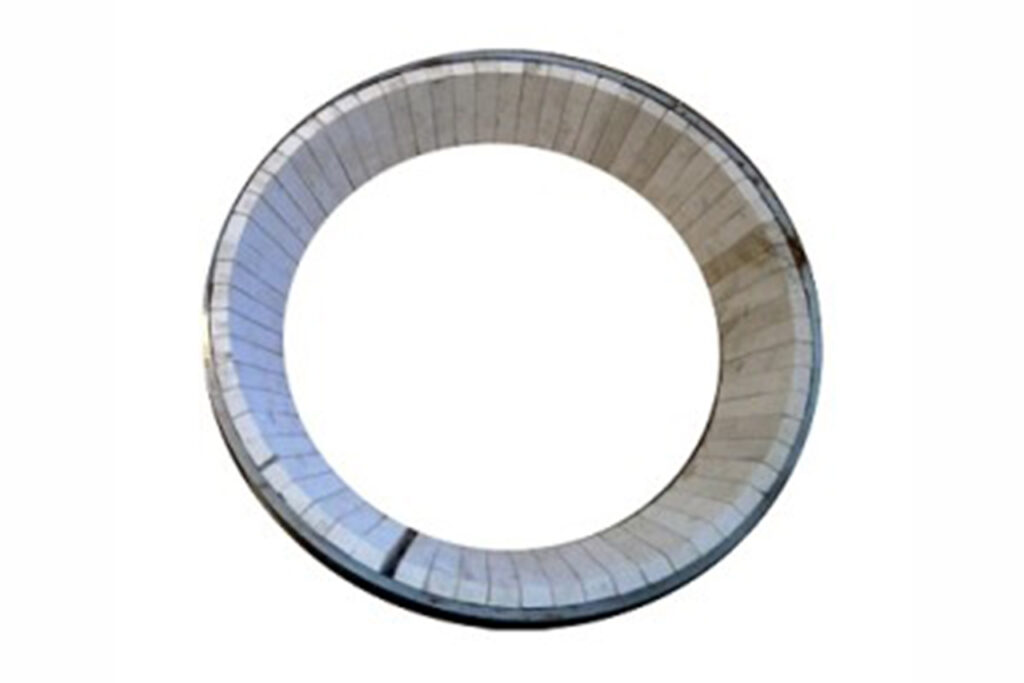

- Ceramic Lined Pipe Fittings

- Alumina Ceramic Tiles

- Ceramic Bends and Elbows

- Ceramic Orifices

- Porous Ceramic Media

Fluorescent and Decorative Ceramic Tiles

Consequently, all of our products have exceptional wear characteristics, thermal stability, and mechanical strength, proven suitable for all aspects and applications of cement plants, steel industries, mining, power generation, and oil and gas fields.

What makes Unick Control System the perfect partner?

Proven reliability: As a ceramic-lined pipe fittings supplier with years of experience.

Quality: Our products are manufactured to the highest international standards of performance and safety.

Innovative Engineering: We develop and supply innovative and evolving solutions for your industrial-specific performances.

On time: Our robust processes ensure complete supply, on time to meet your schedule and project commitments around the globe.

Build A Sustainable Industrial Future

At Unick Control System, we provide superior, ceramic industrial solutions that typically extend the life of industrial equipment and that often eliminate or significantly reduce your industrial maintenance costs! Our ceramic products are innovative materials.

Properties Of Alumina Ceramic Tiles

| Aluminia (Al2O2) Content | 90% (Minimum) |

| Bulk Density | 3.3 – 3.6 gm / cc |

| Cold Crushing Strength | More than 3000 kg/sq. cm |

| Flexural Strength | More than 2200 kg/sq.cm |

| Water Absorption | Less than 0.1% |

| Abrassion test loss in gms. | 0.03 max. |

| Jet errosion test loss in gms | |

| (a) 45 degree | 0.02 max. |

| (b) 90 degree | 0.04 max. |

| Coeff of thermal expansion | 7.2 x 10-6 per degree C (Min.) |

| Service Temp. to withstand | 1000 degree C (Max.) |

| Hardness | 9 MOH |

| Min. thickness of Ceramic Lining | 20mm |

| Min. thickness of Bonding Material | 10mm |

| Guaranteed Life | Minimum 20,000 running hrs. for Ceramic Lined Bends & Elbows and 15000 R/Hrs. for Ceramic Lined Orifices. |

Fluorescent Tiles

| PRODUCT INFORMATION | |

| Blue Porous Media | |

| Material | Fused Alumina |

| Chemical Nature | Amphoteric |

| AI2O3 Content (Typical) | 82% |

| Bulk Density (Max) | 2.3gm/cm3 |

| Max.Muse temprature | 900° C |

| Oxidation/ Reduction Effetc | Nil |

| Reaction Wuth Acids | Mild Attack by aqua regia/or HF |

| Reaction Wuth Alkalies | Very slight with very strong hot solution |

| Permeability | 15-18 cfm/ft2/inch. flow of air at 75° F & 25%humidity |

| Porosity | 30% – 40% |

| Max. MParticle retention | >25µ |

| Modulus of RuptureDryWet | 150Kgs/cm2120Kgs/cm2 |

| resistance to heat | Excellent |